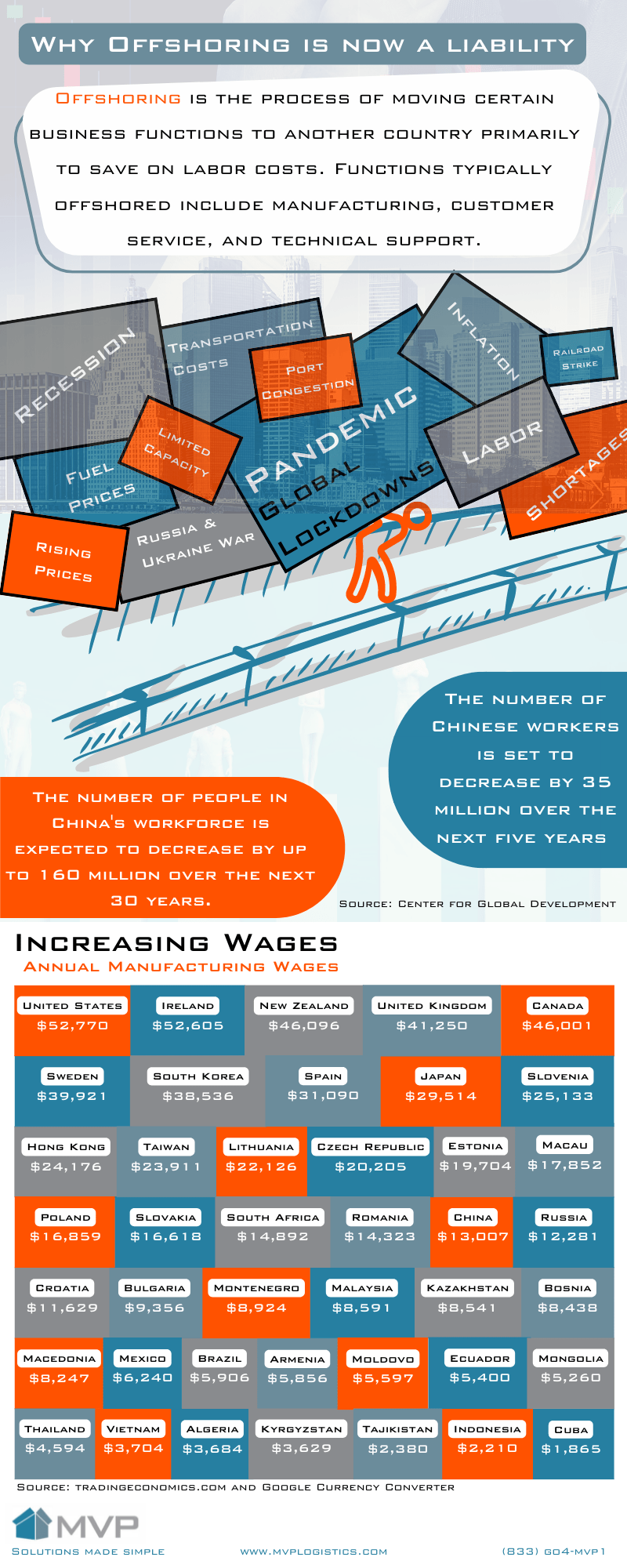

The pandemic made us realize there are risks in the global supply chain we never thought about before.

Businesses are realizing it might be a bad idea to get manufacturing and sourcing from other countries because of the risk, which may come with a heavy cost.

In a world where global events can disrupt supply chains, it may be wiser to choose products sourced and manufactured closer to home.

It is time to rethink sourcing strategy towards nearshoring and reshoring to mitigate risks and ensure the continuity of supply.

The Definition of Offshoring, Nearshoring and Reshoring

Offshoring is the process of moving certain business functions to another country primarily to save on labor costs. Functions typically offshored include manufacturing, customer service, and technical support.

Offshoring is not outsourcing. Outsourcing is often confused with offshoring, but the two terms are not interchangeable.

Outsourcing is the contracting of business functions to an external provider. The provider can be based in the same country or abroad. A company that outsources a function is not interested in being responsible for the execution of the outsourced business functions. They would rather pay another company to complete these business functions on their behalf.

Nearshoring is the process of moving certain business functions to a country near your own. The main motivation for nearshoring is to lower costs, reduce the distance between you and your customer base, or target market.

Reshoring the process of returning production, manufacturing, and sourcing of goods back to the company’s country of origin.

Insourcing is when a company take responsibility for the execution of business functions within their own organization that were once outsourced.

The Benefits of Offshoring Manufacturing and Sourcing

There is more competition now because people can sell things to each other from anywhere in the world using the internet.

This has put pressure on companies to find ways to spend less money. For many companies, this has meant moving some of their operations to other countries (offshoring), where the cost of doing business is less.

Offshoring Allows Companies Access to Larger Pools of Talent at Lower Wages

Offshoring is the utilization of certain labor-saving devices to cut costs.

- Companies can avoid unionization and the associated costs

- Employees are paid at lower wages, often without benefits

- Regulations may allow for companies to require more from their employees

In other countries, more people may be available for work, and they may have skills that are more desirable to a company.

This means there is less needed to train new employees on how to perform their job.

It opens the door for the possibility of providing 24/7 service.

If companies pay their workers less money, they can make their products for less money. This means the company can sell the product to consumers for less money.

Offshoring Offers Companies the Ability to Reduce Overhead Costs

If a business is in an area where the cost of living is lower, the company can save money on expenses like rent, utilities, transportation, etc.

Lower prices also mean the company has more money to spend, bonus, or distribute as dividends.

Companies may also take advantage of volume discounts because they are able to purchase more.

Spending less money and selling for more equals higher profit margins and competitive advantage.

The Drawbacks of Offshoring Manufacturing and Sourcing

When a business gets its supplies from other countries, it can become vulnerable to disruptions in their supply chain.

This is because there is no guarantee these goods will always be available, or affordable.

Rise of the Middle Class in Developing Countries Has Led to Higher Labor Costs

The middle class is growing in developing countries. They want to have better working conditions and more money for the work they perform.

This is putting pressure on companies offshoring to raise their prices for consumers.

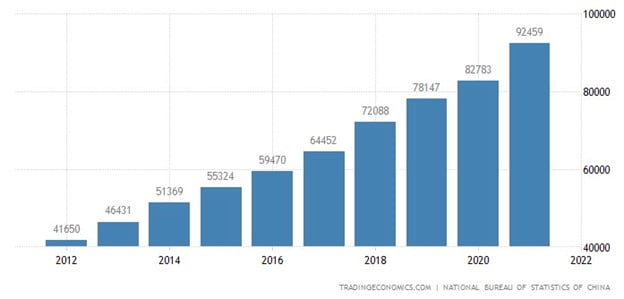

The average yearly wage for manufacturing workers in China has grown by 122% since 2014, from 41,650 CYN ($5,746 US Dollars) to 92,459 CYN ($12,756 US Dollars) in 2021.

Source: China Average Yearly Wages in Manufacturing (tradingeconomics.com)

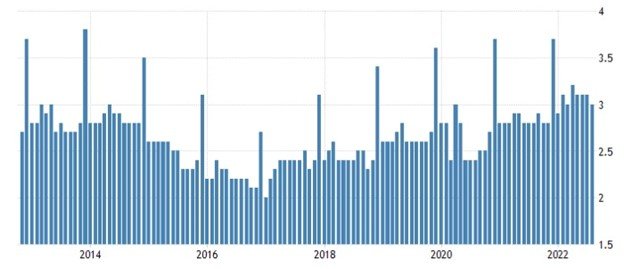

Whereas Mexico’s wages not increased for the past 15 years. They have stayed the same at an average of $2.65 USD per hour from 2007 to 2022. Analysts think wages might increase to $4.00 USD in 2023.

Source: Mexico Nominal Hourly Wages in Manufacturing (tradingeconomics.com)

This begs the question, why aren’t more companies considering Mexico over China?

The Cost of Shipping Goods Has Increased Due to the Rising Price of Oil

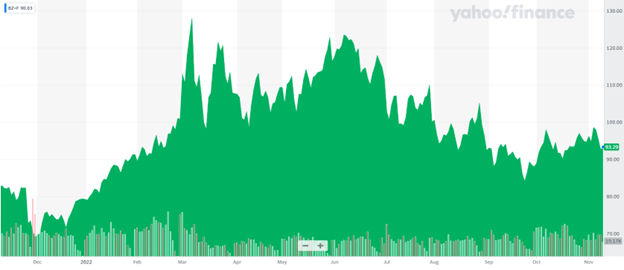

The increased cost of shipping goods is one of the most significant drawbacks of offshoring. A barrel of Brent Crude oil cost $$82.17 on year ago. Now it costs $93.49, which is 13% more expensive.

The conflict between Russia and Ukraine caused the price to go up to $122.01 in June 2022, which is a 48% increase in cost.

Source: BZ=F Interactive Stock Chart | Brent Crude Oil Last Day Financ Stock – Yahoo Finance

The price of things is always changing. Companies cannot count on the price of things to stay the same.

When unplanned expenses happen, companies need to find extra money to pay for these sudden changes.

For example, in December 2016 it cost $1,557.27 to ship a 40-foot container from China to the West Coast, but by September 2021, that same trip cost $20,586.11, which is 1,221.93% more expensive.

Source: FBX01 Asia to West Coast | Maritime Shipping | Collection | MacroMicro

The cost to ship a container from North America West Coast to China also went up a lot between 2016 and 2021. In December 2016 it cost $1,524 to make that trip, but by September 2021 it was 628% more expensive at $11,109.

Source: FBX China/East Asia – North America West Coast – Freight Rate Index (freightos.com)

How would an increase cost of $19,028 per container impact your company if you were shipping products from China to the United States?

The Rise of Automation and Robotics in Manufacturing

The manufacturing industry has changed a lot in recent years thanks to advances in automation and robotics.

Companies are embracing these changes because of factors such as:

- Improved accuracy, consistency, quality, and yield

- Greater efficiency and productivity

- Enhanced worker safety

- Less vulnerability to labor shortage

- Using humans for higher value activities within their organizations

- Data driven decisions and processes

Plus, humans need things such as food, coffee breaks, and rest. Not a machine.

Aging Workers + Shrinking Population – Disinterested Younger Folks = Trouble

As Baby Boomers reach retirement age and Millennials enter the workforce, there is a looming issue facing businesses: an aging workforce combined with a shrinking pool of young workers to take their place.

While it may seem like a simple fix to just hire anyone to fill vacancies, the lack of interest in traditional industries from younger generations means companies will struggle to find qualified candidates for positions not deemed “cool” or trendy.

Companies need to adapt by offering more flexible work options, providing training and education opportunities, and offering competitive salaries and benefits if they want to attract and retain top talent from all age groups.

The younger generation also has less bodies, which means there will be a major labor shortage.

Less people also mean less consumption.

Sprinkle in environmental regulations to protect our environment and we have a manufacturing industry that needs to adapt.

They would need to focus on developing the infrastructure to support their manufacturing.

Which would not include a low skill labor market that offshoring offers.

Those who fail to plan – plan to fail. Correct?

The Benefits of Nearshoring and Reshoring Manufacturing and Sourcing

Give the United States Customer Base What They Want

The Reshoring Institute surveyed 500 Americans about purchasing products manufactured in the United States and 70% said they would prefer American-made products, with 83% stating they would be willing to pay up to 20% more for products made domestically.

Isn’t the customer always, right?

Then wouldn’t it be wise to consider giving your market what they want – products manufactured and sourced in the United States.

Shortening the Lead Time in all Areas of Your Supply Chain Will Reduce Risk

When it comes to managing the risks in your global supply chain, the closer you keep your sources, the better.

While offshoring may seem like a cost-effective solution, having less control over where materials and products come from can lead to unforeseen roadblocks.

Nearshoring and reshoring as part of your sourcing strategy allows you to work with vendors in closer proximity, which allows for greater oversight and management.

This not only helps to reduce potential risks, but it can also improve responses to market changes and increase overall supply chain efficiency.

Tighten your grip on your supply chain – your business will thank you for it.

Higher Company Control Within Your Supply Chain the Lower the Risk

When it comes to managing risk within your supply chain, the old saying “If you want something done right, do it yourself” rings true.

The more control a company has over its supply chain, the lower the potential for unexpected hiccups or disruptions.

Globalization has certainly made it possible for companies to expand their sourcing strategies and access to new and diverse markets, but it also introduces risks that can be mitigated by having a greater degree of control.

Nearshoring and reshoring are becoming more popular as businesses work to bring manufacturing closer to home and increase oversight of their suppliers.

In today’s unpredictable global economy, having a tight grip on your supply chain may just be the ticket to avoiding disastrous consequences.

The moral of the story is, don’t put all your eggs in one basket. Diversify your sourcing strategy to include nearshoring and reshoring to mitigate risk to your supply chain.

Have you considered reshoring or nearshoring? Let us know in the comments below.